Svitzer Australia

In Australia & Papua New Guinea

Our company

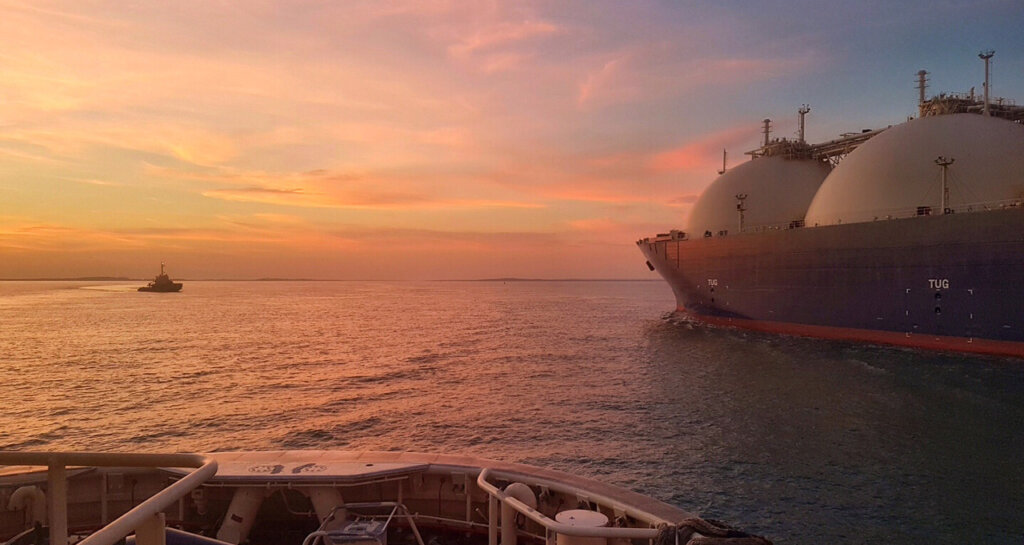

Svitzer has provided safety and support at sea since 1833. We are continuing this tradition as the global market leader within towage and marine related services.

Svitzer provides a crucial link in the Australian supply chain with more than 50,000 tug movements a year, making our ports safer and more efficient. Svitzer Australia is also the largest employer of Australian seafarers.

Svitzer is part of the Maersk Group and are proud to be part of the Svitzer fleet of more than 430 vessels and operations all over the world.

Our services

No one wants to be in trouble at sea, but you can count on us if you are.

Our ports

We have more than 100 vessels within Australia and Papua New Guinea. Find examples of vessels in specific operations.

Newsroom

Press Releases and other news from Svitzer Australia.

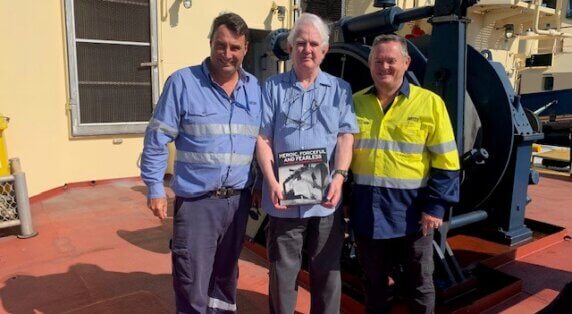

Working with us

We are Australia’s largest employer of seafarers with around 1000 committed and engaged employees.

Australia Head Office

7 Cooper StreetBalmain NSW 2041

Acknowledgement of Country

Svitzer Australia acknowledges the Traditional Custodians of Country throughout Australia and their connections to land, sea and community. We pay our respect to their elders past and present and extend that respect to all Aboriginal and Torres Strait Islander peoples today.